Additive Manufactured Heat Exchangers

Effects on Pressure Drop when Additively Manufacturing Heat Exchangers with Micro-Geometries

Undergraduate research study conducted in 2019 through the Power Optimization of Electro-Thermal Systems (POET) and Air Conditioning and Refrigeration Center (ACRC) at The University of Illinois Urbana-Champaign under the supervision ofProblem Statement

The electrification of vehicles is on the rise, and it is expected that millions of EVs will be manufactured over the next decade. Developing effecive battery thermal management systems is critical in ensuring long-lasting, safe batteries. Additive manufacturing (AM) has been investigated for the rapid prototyping of heat exchangers (HXs). However, can AM be relied upon to create prototype heat exchangers with comparable properties to conventionally-made HXs?

Objectives

- Study the limitations of Direct Metal Laser Melting (DMLM)

- Increase the quality of DMLM-made HXs

- Achieve low pressure drops across HXs

Methods

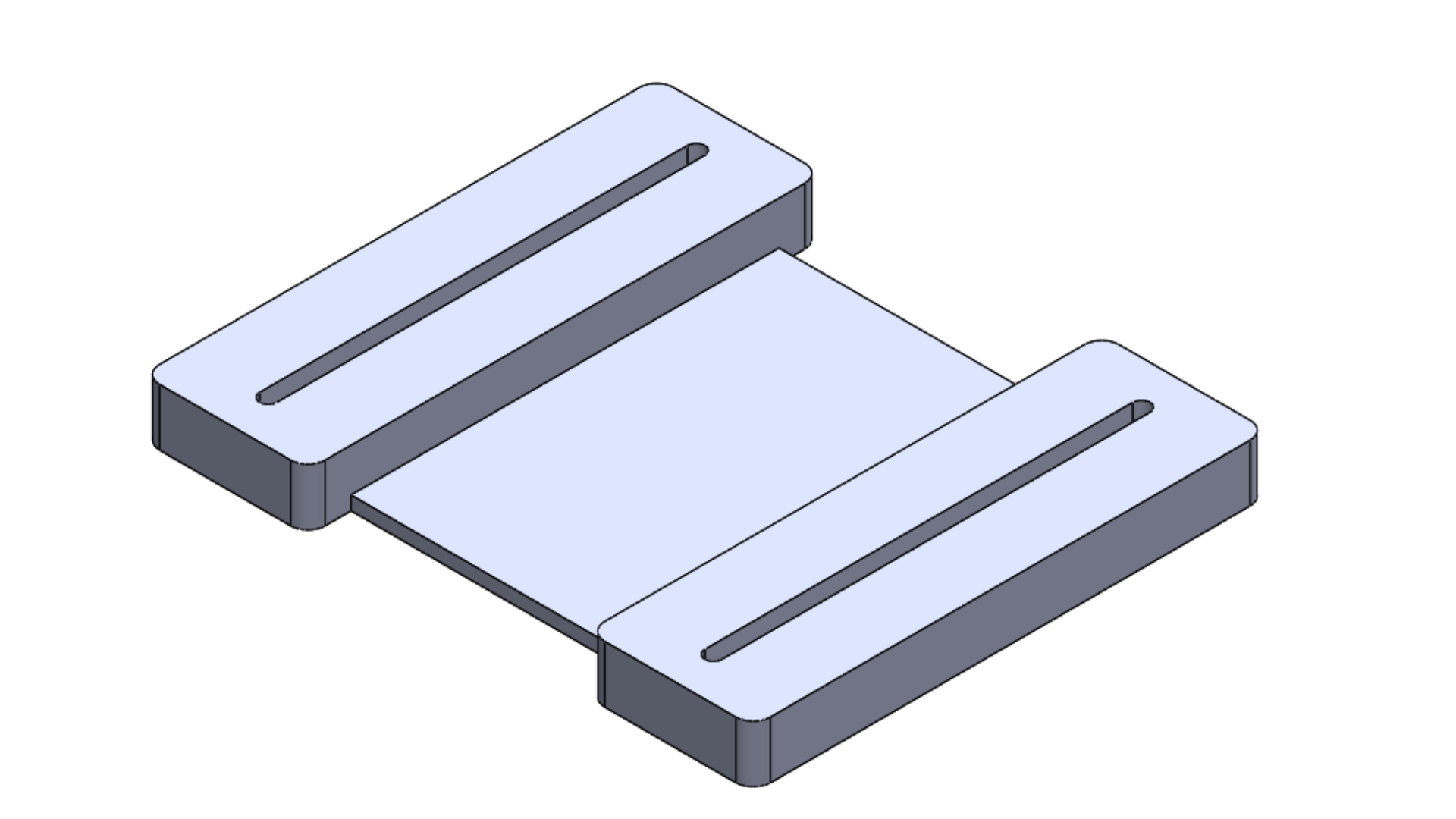

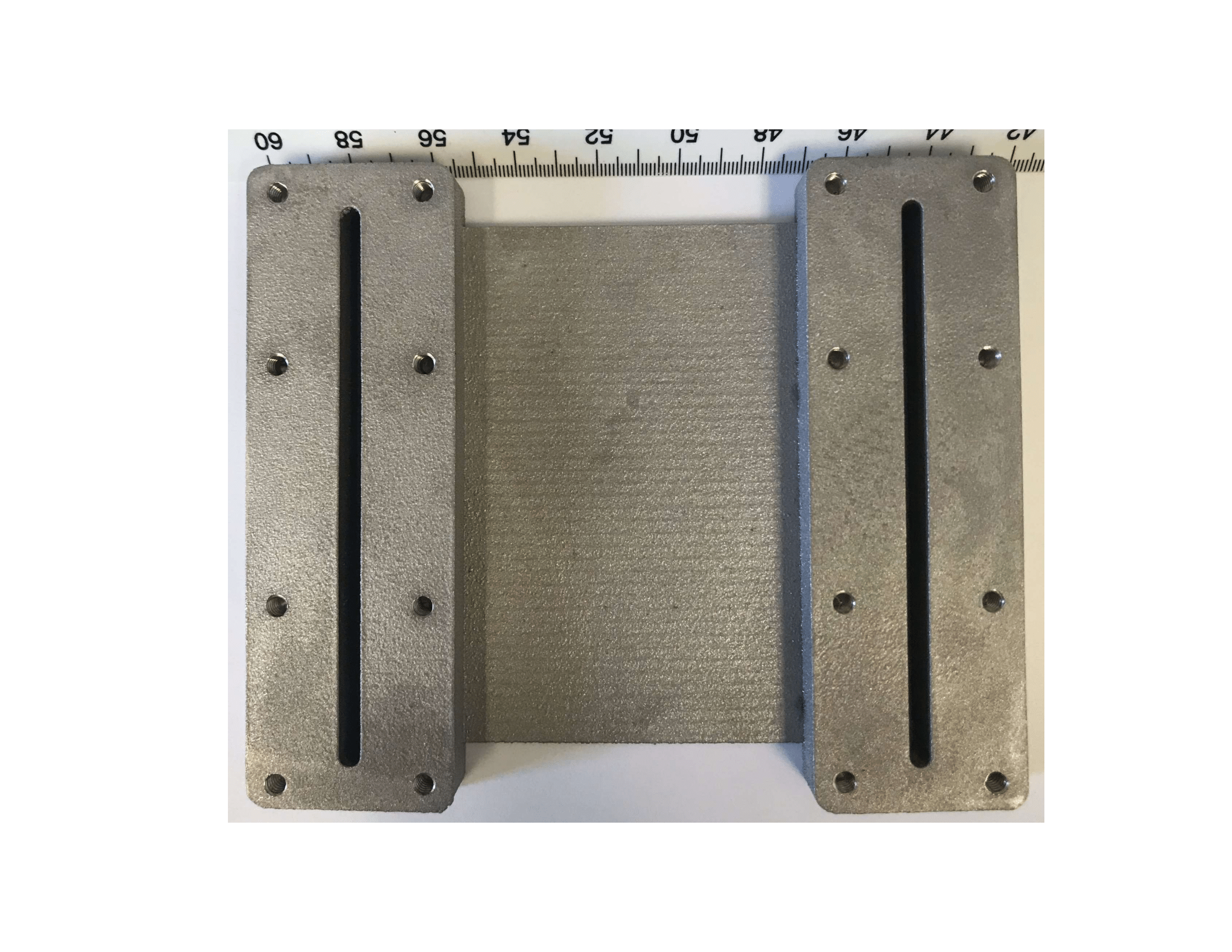

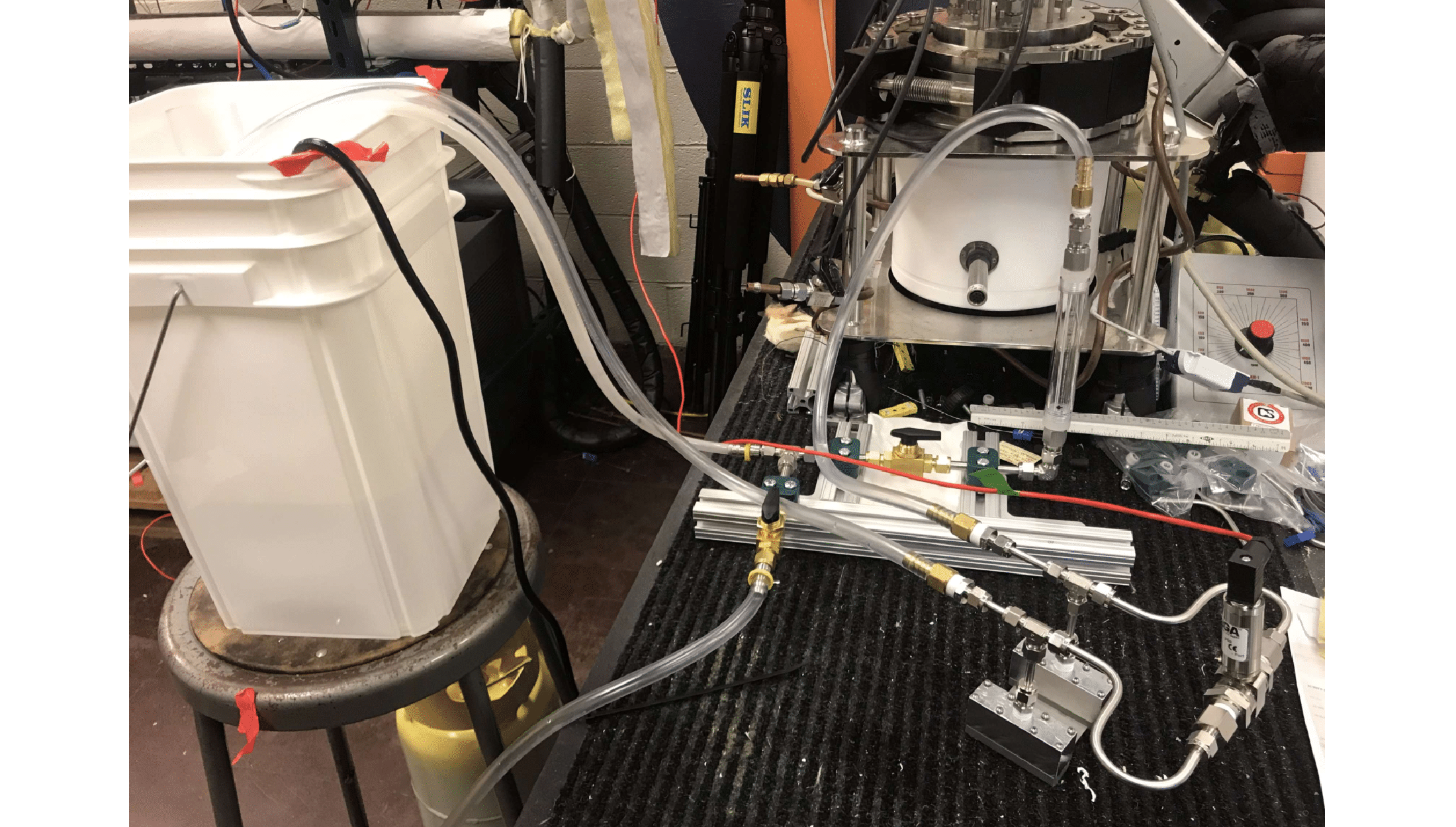

A literature review informed the design of heat exchanger, ensuring all surfaces could be built upon and that round microchannels would be formed within the body of the HX. Three HXs were printed using different metals, and a pressure rig was built to control and measure the pressure differential across the HXs.

Results

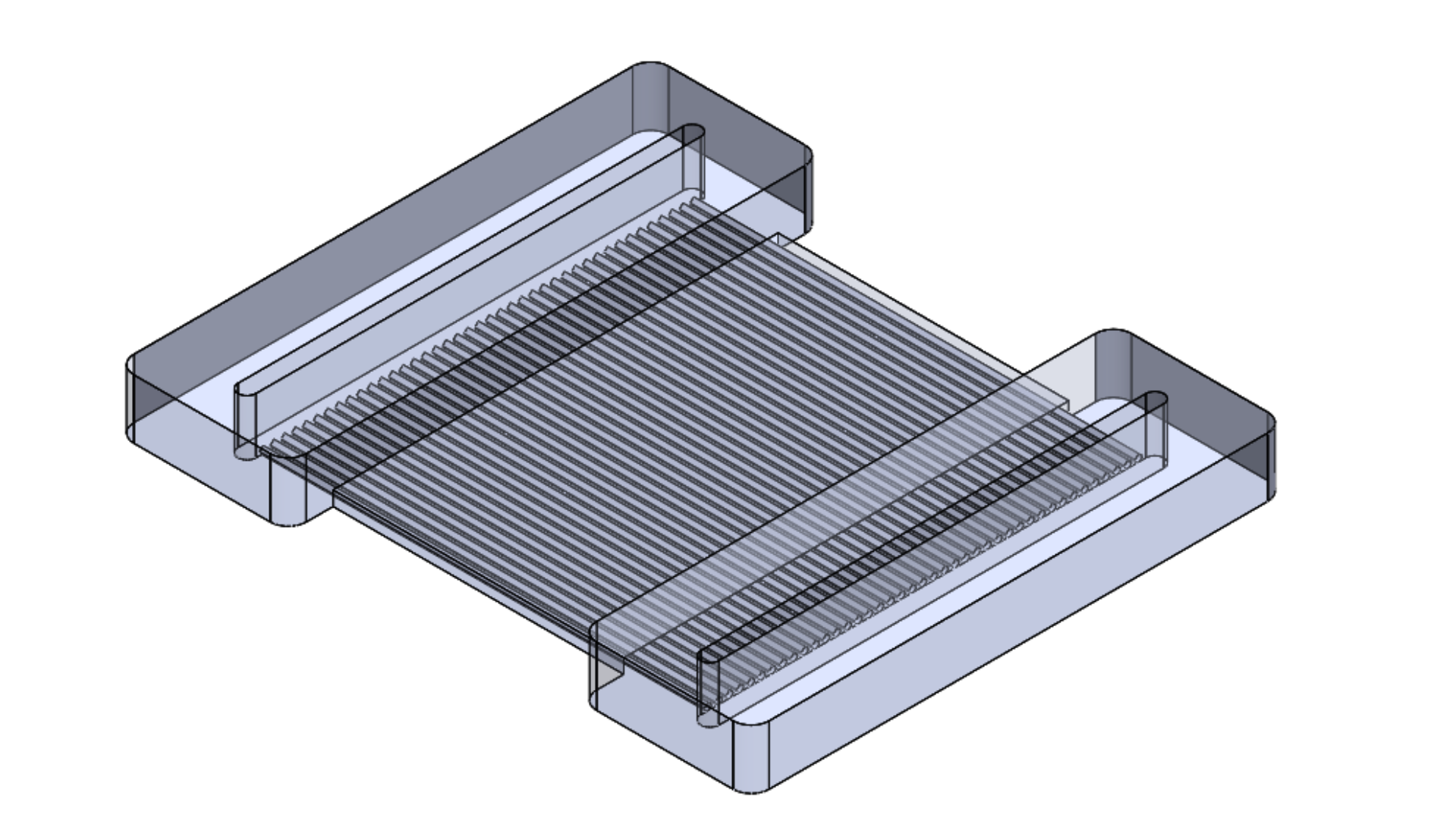

AM results in HXs with low compliance, high roughness, and high porosity. As shown in a CT scan, the inner channels have high variability and roughness, both being detrimental to the pressure drop. Additionally, the porosity resulted in air and water escaping through the walls of the HX.

Conclusions

Additive manufacturing is a potentially useful tool for rapid prototyping. However, unless the problems of high roughness and porosity can be resolved by adjusting the HX design and AM printer parameters, this resource may prove difficult to practically utilize.

Acknowledgements

This research project was done under the mentorship of Dr. Nenad Miljkovic and Dr. Allison Mahvi within the Energy Transportation Research Lab at the University of Illinois at Urbana-Champaign over the Summer of 2019. It was conducted with the generous financial support of the Air Conditioning and Refrigeration Center (ACRC #449) and the National Science Foundation Engineering Research Center for Power Optimization of Electro-Thermal Systems (POETS) with cooperative agreements EEC-1449548 and REU Site EEC 16-59794. I would like to extend a special thank you to Allison Mahvi and Camilo Jaramillo Correa for supporting my research and giving me wonderful guidance.